Recipe Creation Process¶

The recipe is the base of your product batch preparation and will serve as a guide line during the process. Thank to it, you are sure that the data collected during your experiments or the products sent to your customers are consistents on their quality. It will also helps tech transfer teams whom have access to all the R&D data.

Note

Only one recipe can be specified to a product

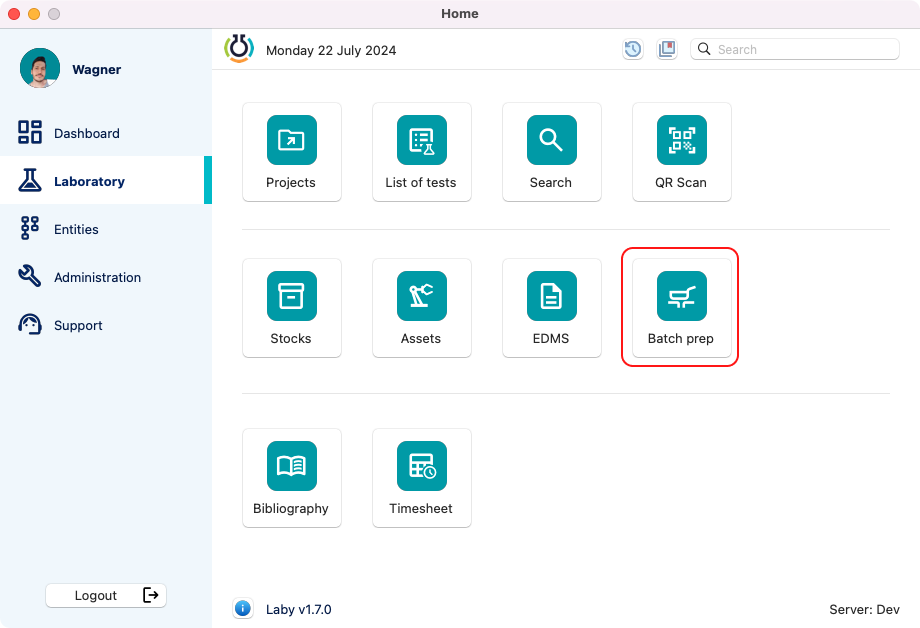

Step 2: Create a new recipe¶

Click on “Recipes”, “Create” button and select the product you want associate a recipe.

Use the filter to find quickly the related product.

Product picker located on the recipe creation.¶

Tips

Here you can select a product from the stocks/inventory module. If the product doesn’t appear, you must create it on the inventory.

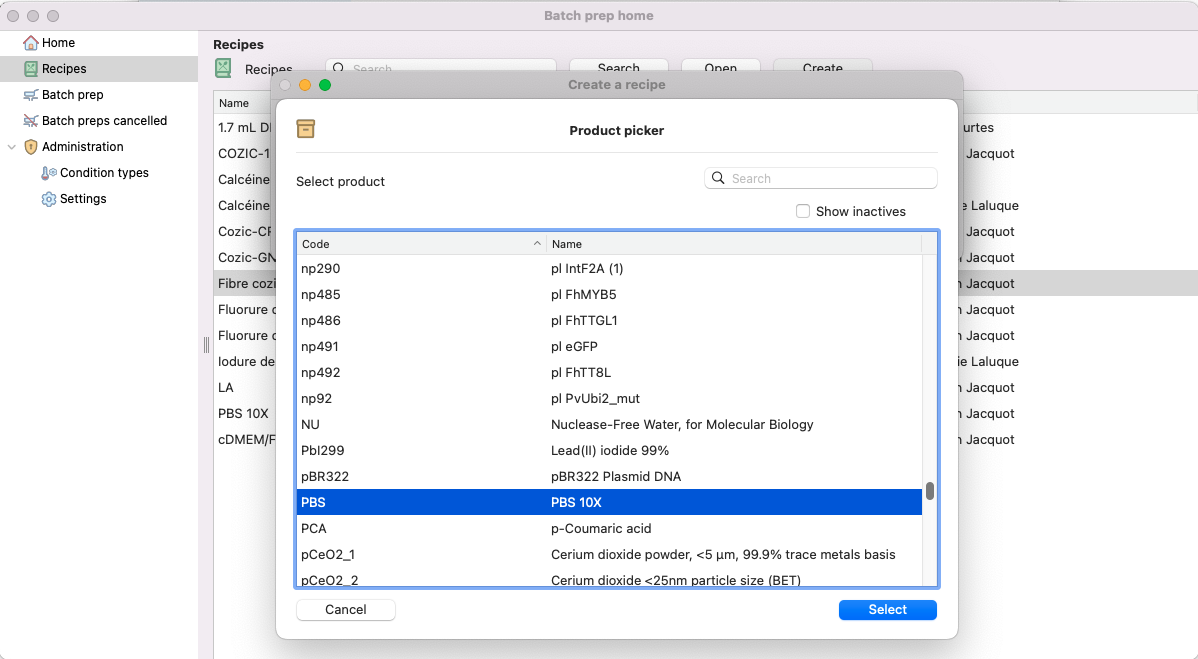

Step 3: Open the newly created recipe¶

Open the new recipe.

Define the product quantity that the recipe will be based on.

Optionally, add a general gescription.

Detailed window from the recently created recipe.

¶

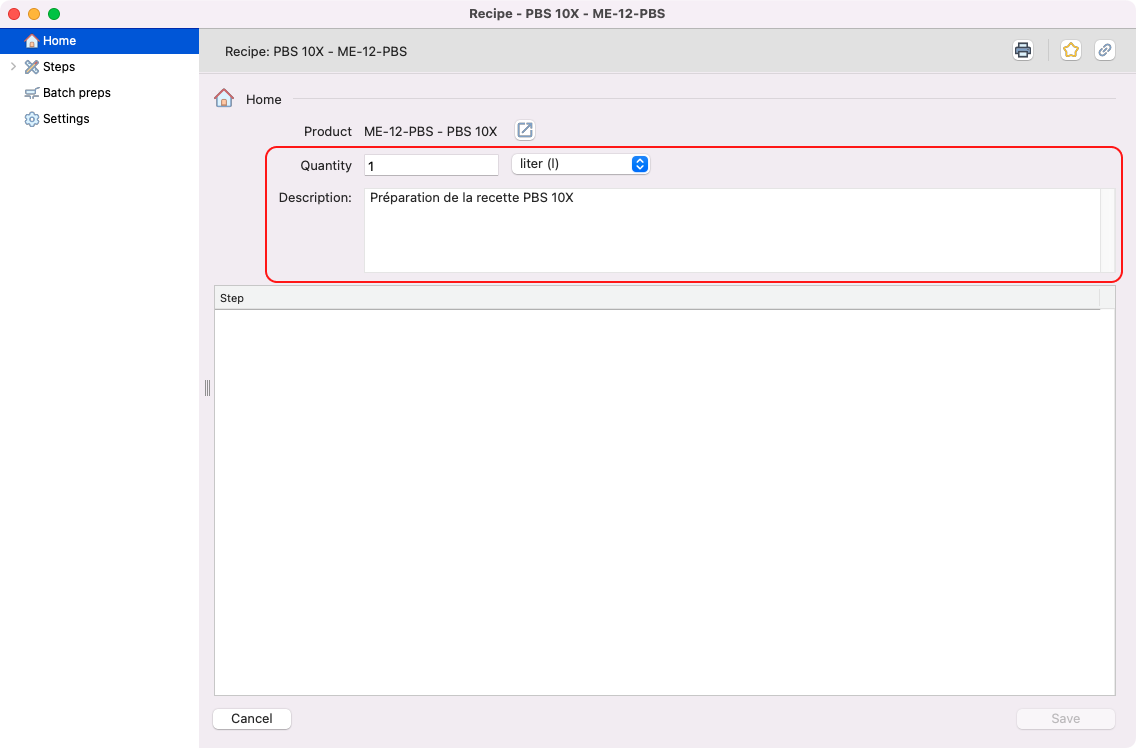

Step 4: Add steps¶

Include all the steps needed for your recipe. In the next step you’ll have more information about how to fill them.

Steps view inside a recipe.

¶

Step 5: Precise each step¶

Check how to fill each step input:

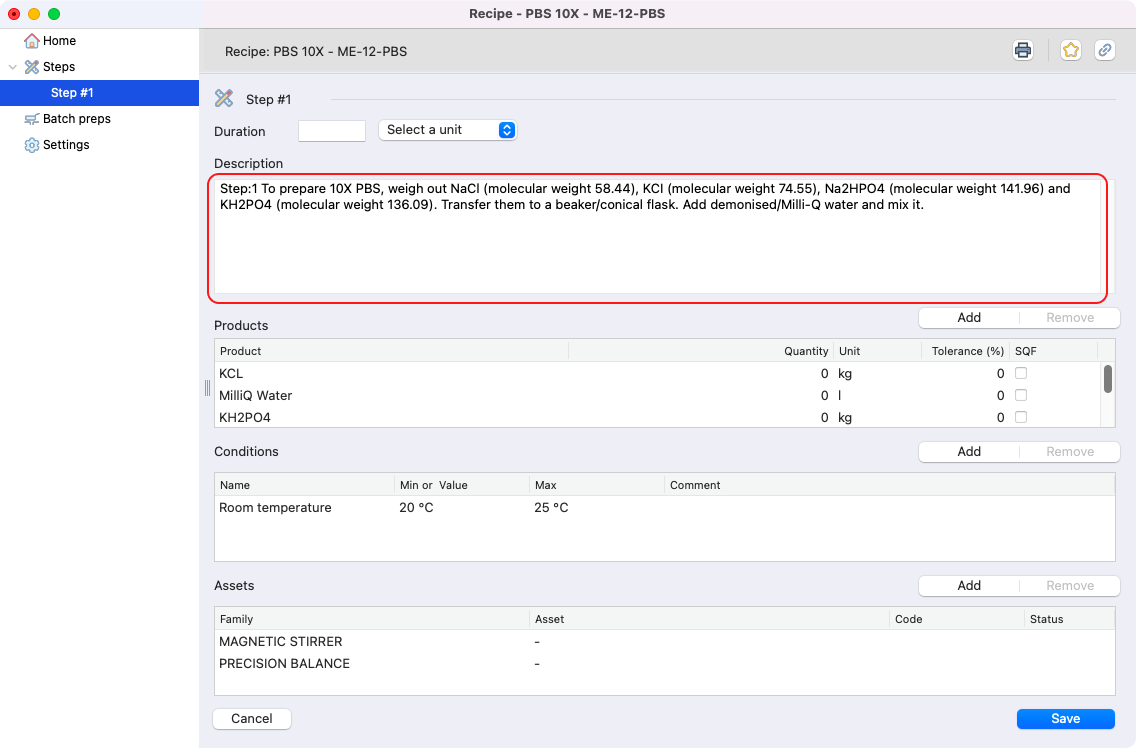

General step description and theoretical duration:

Step description highlighted.

¶

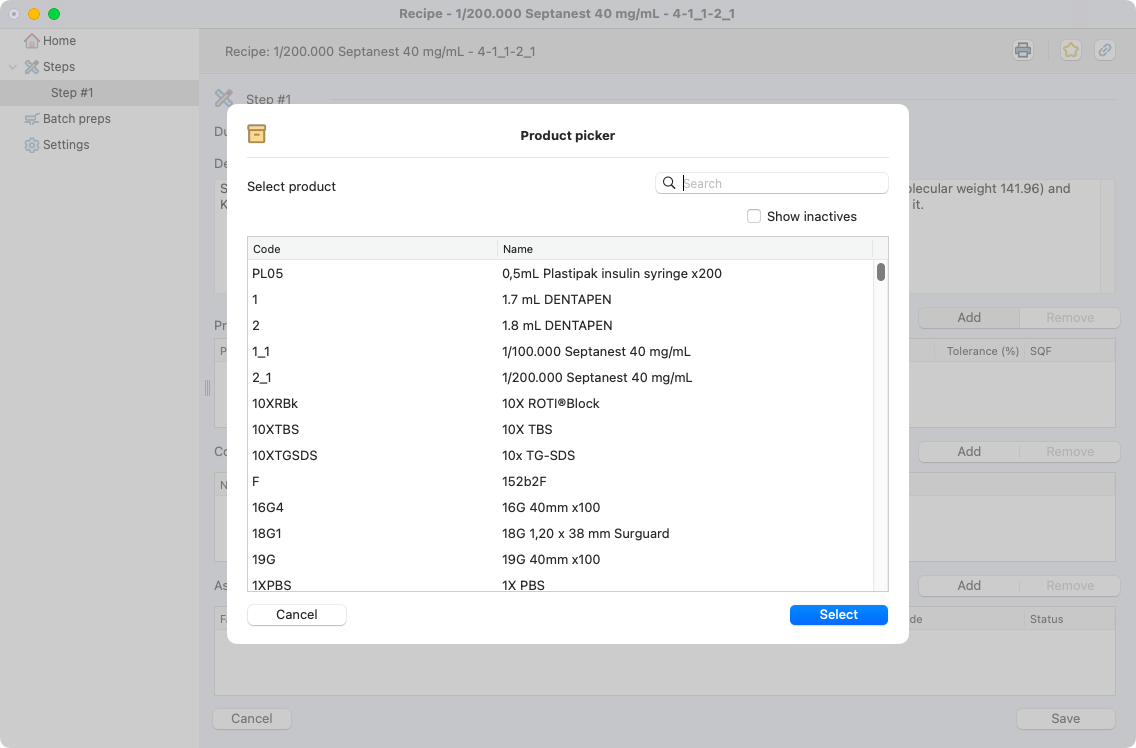

Product(s) with their quantity and acceptable error margin:

Product selection.

¶

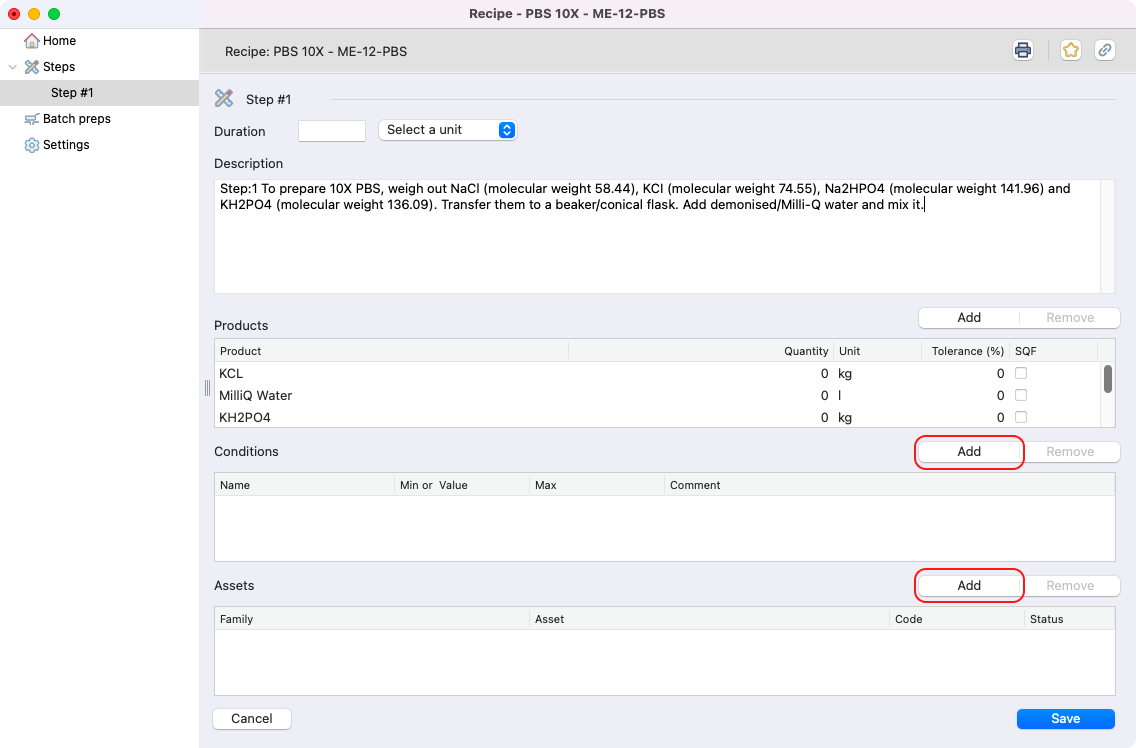

Condition(s) (duration, temperature, pression, environment, etc.).

Equipment(s) subfamily and equipment (optional):

Condition and asset inputs highlighted.

¶

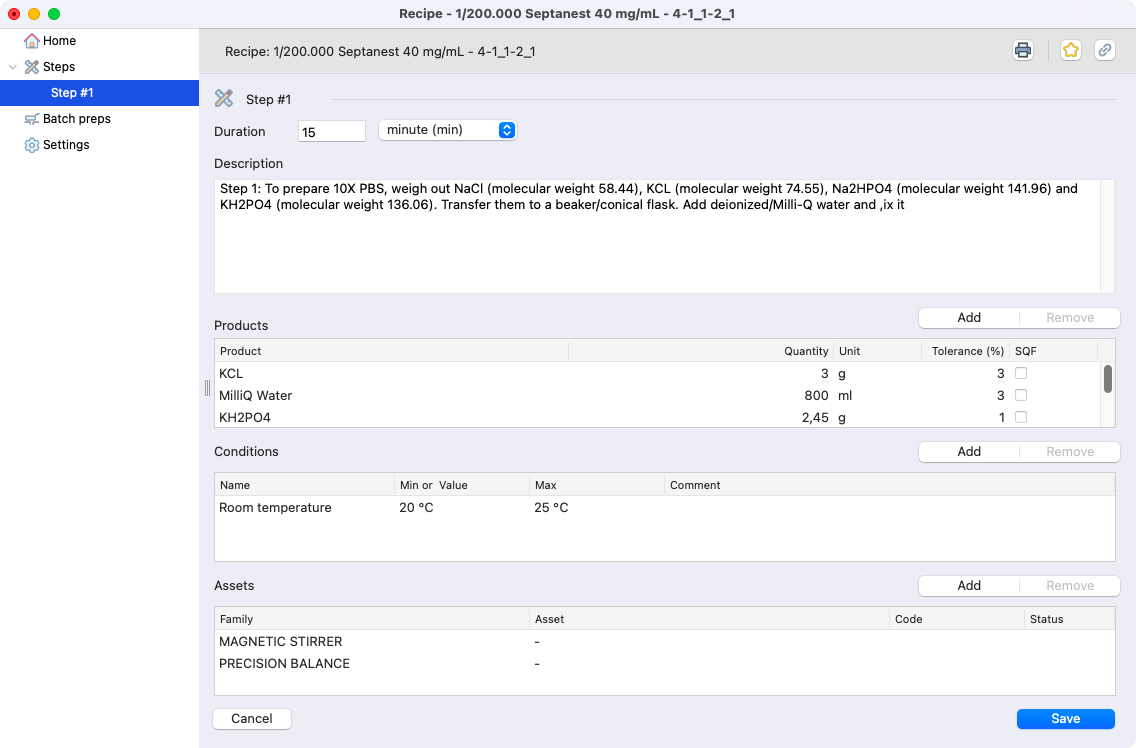

Example of a filled step¶

Here is how it should look a completely filled step on your recipe:

Filled step on a recipe.¶

Tip

Here you can eventually create a pdf version of the recipe (printer icon).